Biogas use in Reconstruction

Practical Action

Plug Flow Digester

This is a type of Earth-pit plant, therefore appropriate in stable soil (e.g. laterite), where masonry

digesters are not necessary. Earth-pit plants can only be recommended for installation in

impermeable soil located above the groundwater table. Their construction is particularly

inexpensive in connection with plastic sheet gas-holders.

For earth-pit plants, it is sufficient to line the pit with a thin layer of cement (wire-mesh fixed to

the pit wall and plastered) in order to prevent seepage. The edge of the pit is reinforced with a

ring of masonry that also serves as anchorage for the gas-holder. The gas-holder can be made of

metal or plastic sheeting. If plastic sheeting is used, it must be attached to a quadratic wooden

frame that extends down into the slurry and is anchored in place to counter its buoyancy. The

requisite gas pressure is achieved by placing weights on the gas-holder. An overflow point in the

peripheral wall serves as the slurry outlet.

Advantages: Low cost of installation (as little as 20% of a floating-drum plant); high potential for

self-help approaches.

Disadvantages: Short useful life; serviceable only in suitable, impermeable types of soil.

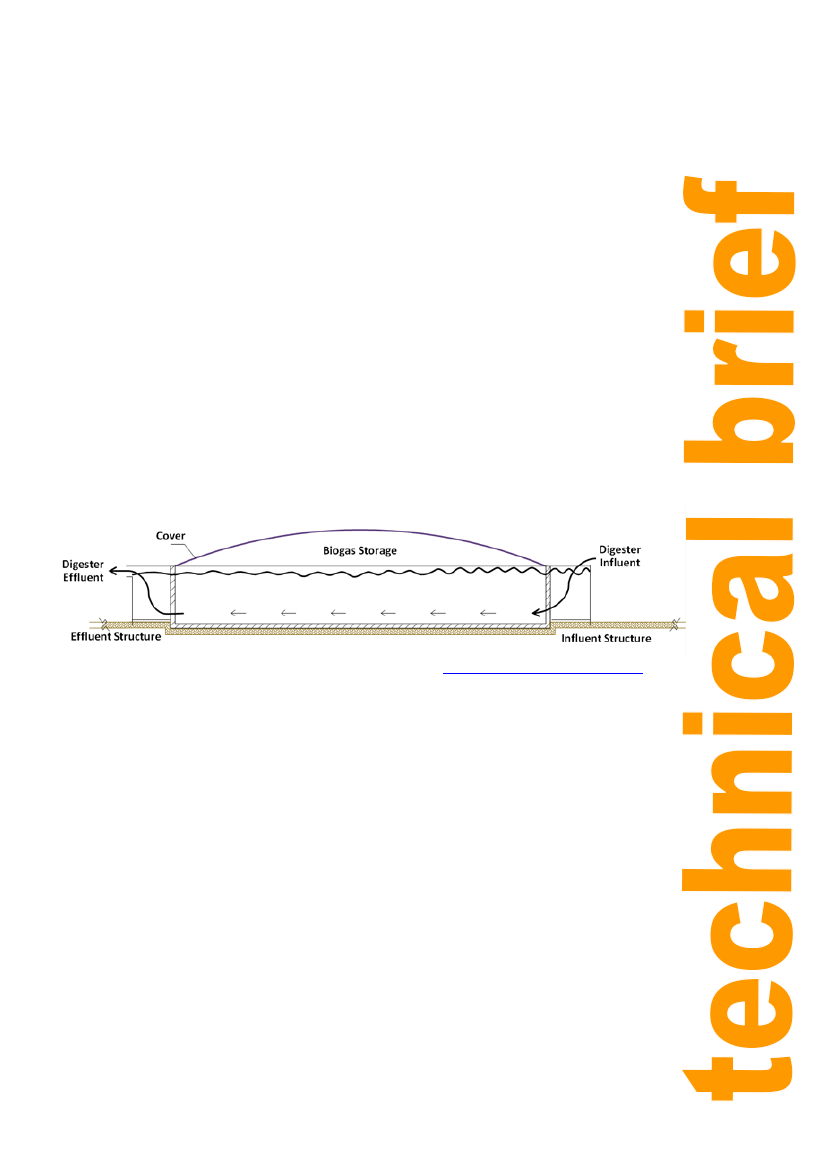

Plug flow digesters (Figure 3) constitute a type of earth-pit plants that have long, narrow concrete

tanks with either a rigid or flexible cover. The vessel is a long narrow (typically a 5:1 ratio; 5 times

as long as the width) insulated and heated tank made of reinforced concrete, steel or fiberglass

with a gas tight cover to capture the biogas.

Figure 3: cross-section diagram of a plug flow digester. Source: http://www.plugflowdigester.com/

The plug flow digester (tank) is built partially or fully below grade to limit the demand for

requiring additional heating. Plug flow digesters are used only at dairy operations that collect

manure by scraping. In theory, manure in a plug flow digester does not mix longitudinally on its

trip through the digester but can be imagined to flow as a plug, advancing towards the outlet

whenever new manure is added.

When the manure reaches the outlet it discharges over an outlet weir arranged to maintain a gas

tight atmosphere but still allow the effluent to flow out. In actuality the manure does not remain

as a plug and portions of the manure flow through the digester faster than others and some settles

or floats and remains in the digester. Biogas produced by the digester is used to heat the digester

to the desired temperature.

Excess biogas can be used to run an engine generator. Heat can also be recovered from the

engine generator and used for space or floor heating, water heating or steam production to offset

the cost of purchased electricity, propane, natural gas or fuel oil used on the farm for daily

operations.

5